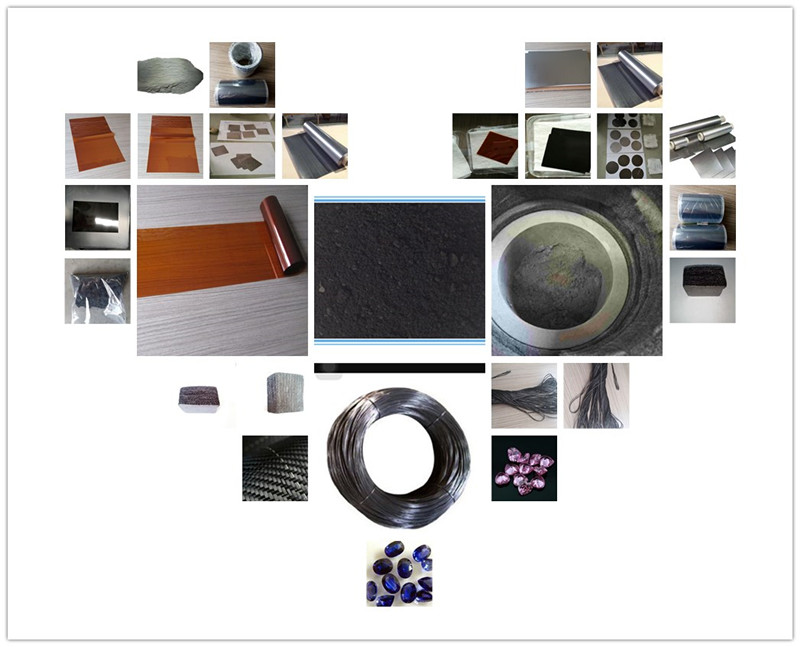

applicable in high temperature graphitization treatment of thermal conductive material graphite film,new materials, carbon and carbon materials, special ceramics industry.

|

model parameter |

lab usage |

production usage |

|||||

|

nti-sml-54w |

nti-sml-98w |

nti-sml-182w |

nti-sml-432w |

nti-sml-576w |

nti-sml-1280w |

||

|

working size |

mm |

300×300×600 |

350×350×800 |

450×450×900 |

520×520×1600 |

600×600×1600 |

800×800×2000 |

|

heating type |

/ |

if induction heating |

|||||

|

control type |

/ |

thyristor control or igbt control ( optional ) |

|||||

|

ht zone capacity |

l |

54 |

98 |

182 |

432 |

576 |

1280 |

|

loading weight |

g |

ht zone capacity × density (g/cm³)×1000 remark:1l=1000cm³ |

|||||

|

ultimate vacuum |

pa |

20 |

|||||

|

if power |

kw |

150 |

200 |

250 |

350 |

500 |

700 |

|

max. working temperature |

℃ |

2850 |

2850 |

2850 |

2850 |

2850 |

2850 |

|

usual working temperature |

℃ |

2800 |

2800 |

2800 |

2800 |

2800 |

2800 |

|

temperature unifomity |

℃ |

±10 |

±10 |

±10 |

±10 |

±15 |

±15 |

|

working environment |

/ |

vacuum or ar, n2 atmosphere protection( micro positive pressure) |

|||||

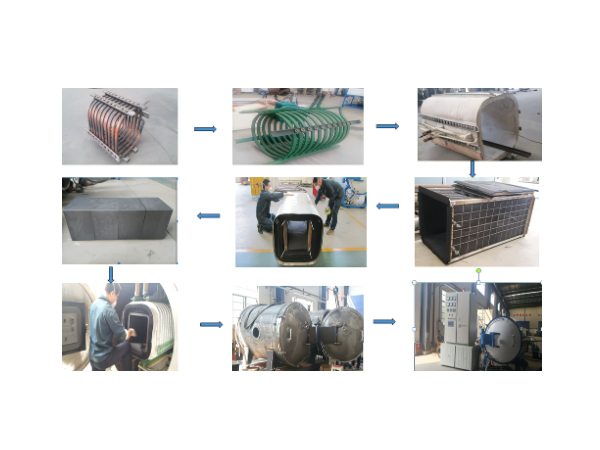

feature:

1.the highest working temperature: 2850℃

2.double layer alumina as keeping temperature material, good the heat insulation and fire resistance effect, less heat loss and quickly heating.

3.equipping with high strength hard composite felt at the bottom of crucible, in order to ensure that the graphite crucible at high temperature level uniform force, it is 1.5 times the service life of similar products.

4.unique design explosion-proof valve of furnace body safe and reliable.